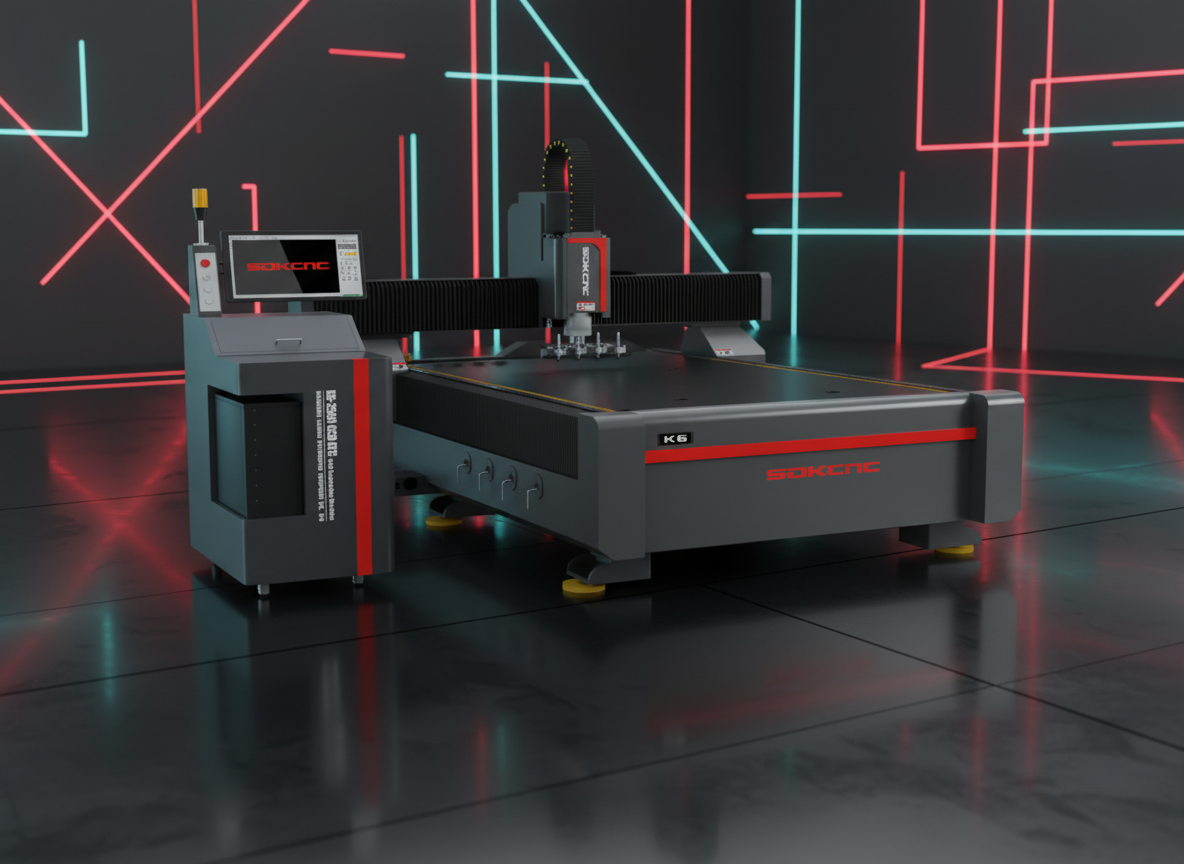

CNC Router

Equipment.

Precision CNC routers for wood, acrylic, aluminum, and composite material cutting and engraving

Maximum Efficiency

Equipped with load-sensing hydraulics that optimize flow for faster cycle times and reduced fuel consumption.

Certified Reliability

Every machine undergoes a rigorous 140-point inspection process before being listed in our inventory.

Service Included

Purchase or rent with confidence knowing our mobile service fleet is available 24/7 for on-site repairs.

Trusted by industry leaders

Available Models

Select a machine to view detailed specifications and pricing.

Frequently Asked Questions

What materials can a CNC router cut?

CNC routers can cut a wide variety of materials including wood (plywood, MDF, hardwood), plastics (acrylic, HDPE, PVC), foam, aluminum, brass, and composite materials. The specific capabilities depend on the spindle power, speed settings, and tooling used.

What is the difference between a 3-axis and 4-axis CNC router?

A 3-axis CNC router moves the cutting tool in X, Y, and Z directions, allowing flat and 2.5D cuts. A 4-axis router adds rotation around one axis, enabling cylindrical work and more complex 3D shapes without repositioning the workpiece.

How often does a CNC router need maintenance?

Regular maintenance includes daily cleaning of debris, weekly lubrication of linear guides and ball screws, monthly inspection of belts and pulleys, and annual replacement of wear items like collets and bearings. Proper maintenance extends machine life and ensures consistent accuracy.

What software is compatible with these CNC routers?

Our CNC routers accept standard G-code and work with popular CAM software including VCarve, Aspire, ArtCAM, Fusion 360, and SolidCAM. Most machines come with basic control software, and our team can assist with software setup and training.

What is an ATC spindle and do I need one?

ATC (Automatic Tool Changer) allows the machine to automatically swap between different cutting tools during a job. This is essential for production environments requiring multiple tool operations, reducing manual intervention and increasing efficiency.

Can't find what you're looking for?

Our procurement team can source specific models based on your project requirements. Contact us today for a custom fleet solution.