Everything US businesses need to know about sourcing CNC equipment from China - quality verification, logistics, hidden costs, and how to get local support.

Why US Businesses Look to China for CNC Equipment

China has become the world's largest manufacturer of CNC machinery, producing everything from entry-level hobby routers to industrial production equipment. For US businesses, this presents an opportunity: quality CNC machines at significantly lower prices than domestic alternatives.

The cost advantages are substantial. Chinese CNC routers often cost 30-50% less than comparable machines from established brands, making advanced manufacturing technology accessible to small shops and startups that couldn't otherwise afford it.

Types of CNC Machines Available from China

CNC Routers

The most popular category for US buyers, Chinese CNC routers cover every application:

- Desktop/hobby routers: 3018-class machines for learning and light work ($200-1,000)

- Mid-size routers: 4x4 and 4x8 machines for production work ($3,000-15,000)

- Industrial routers: Full production machines with ATC ($15,000-100,000+)

CNC Mills and Lathes

Metal-working machines for precision parts manufacturing:

- Benchtop mills for small parts and prototyping

- Vertical machining centers (VMC)

- CNC turning centers and lathes

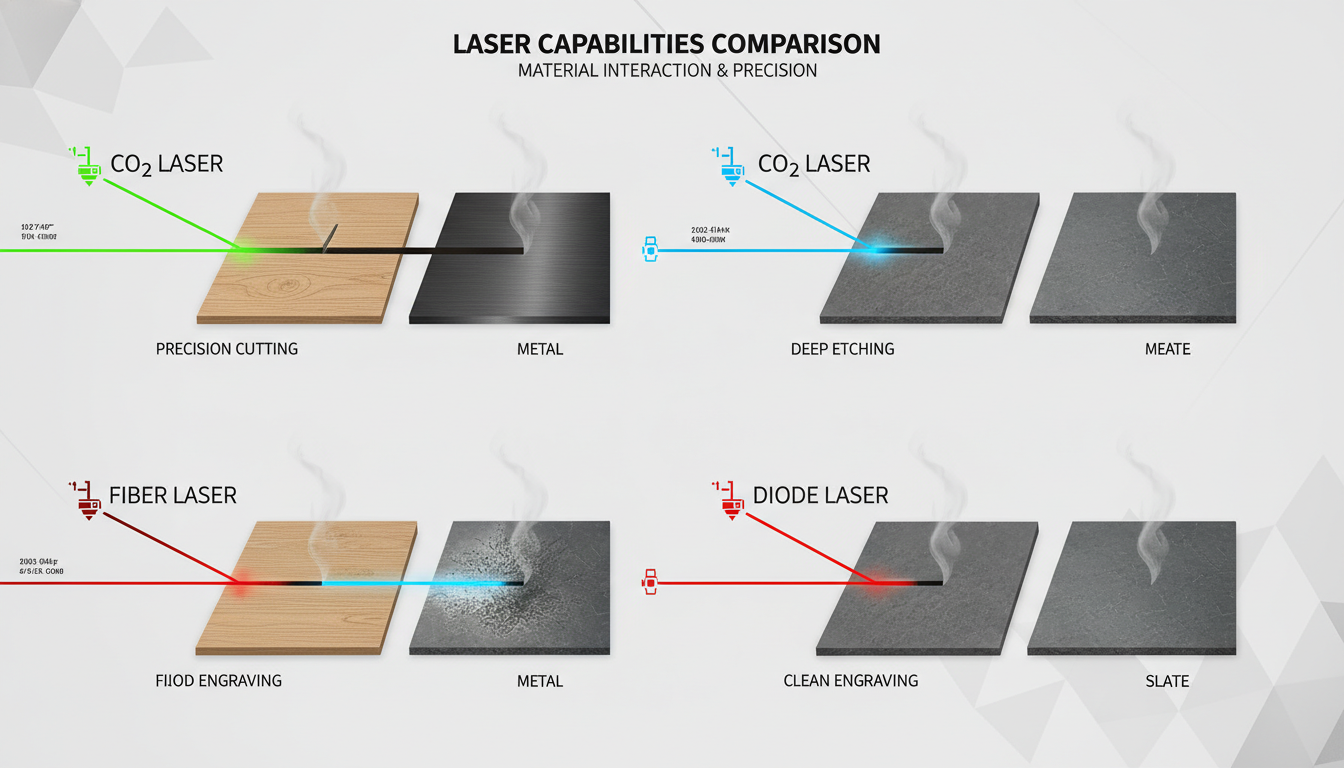

Laser Cutting and Engraving

- CO2 laser cutters for non-metals

- Fiber laser systems for metal cutting

- Combined laser/CNC systems

Specialty Equipment

- Plasma cutting tables

- CNC bending machines and press brakes

- Stone and marble CNC routers

- Foam cutting machines

Browse our equipment inventory to see available machines across these categories.

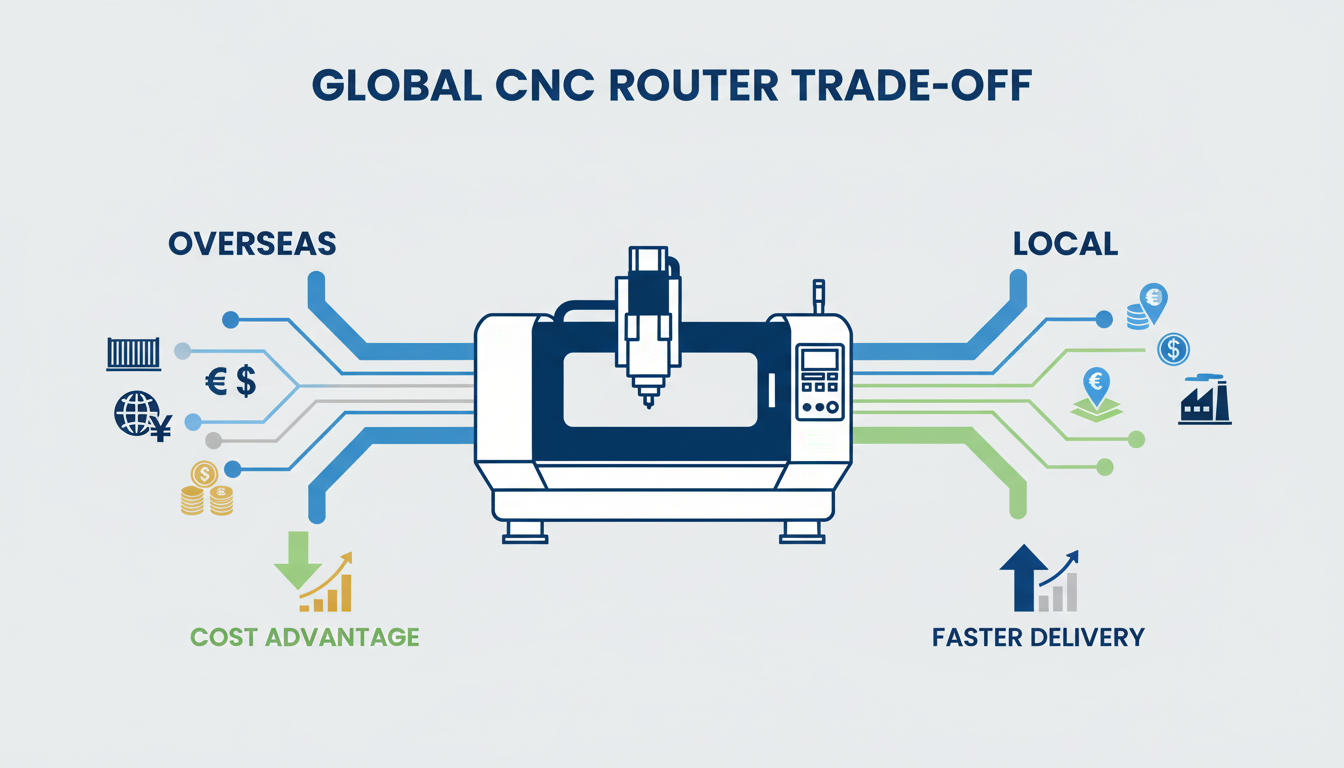

The Real Challenges of Importing Directly

While the price advantages are clear, buying directly from Chinese manufacturers comes with significant challenges that many first-time buyers underestimate:

Quality Inconsistency

Chinese manufacturing quality varies dramatically between factories. Two machines with identical specifications and similar prices can have vastly different build quality, component selection, and longevity.

Communication Barriers

Beyond language differences, there are often misunderstandings about specifications, delivery timelines, and warranty terms. Technical discussions become difficult when precision matters.

No Local Support

When something breaks—and eventually something will—you're on your own. The manufacturer is 12 time zones away, parts take weeks to arrive, and finding a local technician who can work on an unfamiliar machine is difficult.

Logistics Complexity

Shipping heavy machinery across the Pacific involves:

- Freight forwarding arrangements

- Customs documentation and duties

- Final mile delivery for oversized equipment

- Unloading and rigging into your facility

Quality Verification: What to Look For

If you're evaluating Chinese CNC equipment, these factors separate quality machines from problematic ones:

Frame Construction

- Good: Welded steel frames, stress-relieved, properly painted

- Better: Cast iron bases for vibration damping

- Avoid: Thin-wall aluminum extrusion on production machines

Spindle Quality

- Bearing type and expected lifespan

- Runout specifications (should be under 0.01mm)

- VFD (Variable Frequency Drive) quality and compatibility

Linear Motion Components

- Linear rails: Look for recognized manufacturers vs. generic

- Ball screws: Check grade and preload specifications

- Bearings: Quality bearings make a significant difference in precision and longevity

Controller and Electronics

- Controller brand and capabilities

- Driver quality (digital vs. analog)

- Electrical safety certifications (CE, UL)

- Software compatibility with common CAM packages

Hidden Costs of Direct Import

The advertised price is just the beginning. Budget realistically for these additional costs:

Shipping and Customs

- Ocean freight: $800-3,000+ depending on size

- Import duties: Varies by equipment type

- Customs broker fees: $200-500

- Final delivery: $500-2,000 for liftgate and placement

Installation Challenges

- DIY assembly from shipping crates

- Electrical hookup (may require electrician)

- Leveling and calibration without guidance

- Software setup and configuration

Learning Without Training

- Figuring out operation from translated manuals

- Safety procedures learned through trial and error

- Tooling and workholding optimization

Support Vacuum

- Parts shipped from overseas (2-4 weeks)

- No emergency repair options

- Downtime costs when production stops

A Smarter Approach: Pre-Vetted Machines with Local Support

The best way to buy Chinese CNC equipment combines the cost advantages of Chinese manufacturing with the security of local support.

How Equipment Dealers Solve These Problems

- Manufacturer relationships: Dealers work with vetted factories they've inspected and tested

- Quality verification: Machines are inspected before shipping

- Logistics handling: Customs, freight, and delivery managed for you

- Professional installation: Properly assembled, leveled, and calibrated

- Training included: Learn to operate safely and effectively

- Local support: When issues arise, help is a phone call away

- Parts inventory: Common parts available locally

The Value Proposition

Yes, you'll pay somewhat more than direct import pricing. But you're buying:

- Reduced risk of receiving a problem machine

- Professional installation worth days of your time

- Training that accelerates your productivity

- Insurance against extended downtime

- A relationship with people who can help

Questions to Ask Any Equipment Supplier

Whether you're buying direct or through a dealer, ask these questions:

- What specific factory/manufacturer makes this machine?

- What are the actual component brands (spindle, rails, screws, controller)?

- Can you provide references from US customers?

- What warranty is offered, and who honors it?

- How are service issues handled?

- What's the lead time from order to operational?

- What training is included?

- What happens if I have problems after warranty?

Ready to Explore Your Options?

Buying CNC equipment from China can be a smart business decision—if you do it right. The key is getting the cost benefits of Chinese manufacturing without taking on all the risk yourself.

Browse our inventory to see available CNC equipment, or contact our team for a consultation about your specific needs. We'll help you find the right machine and ensure you have the support to keep it running.

Ready to get started?

Browse our equipment inventory or get in touch with our team for expert advice on your next project.