Essential concerns and risks to evaluate before purchasing a CNC router from overseas. Learn what can go wrong and how to protect yourself.

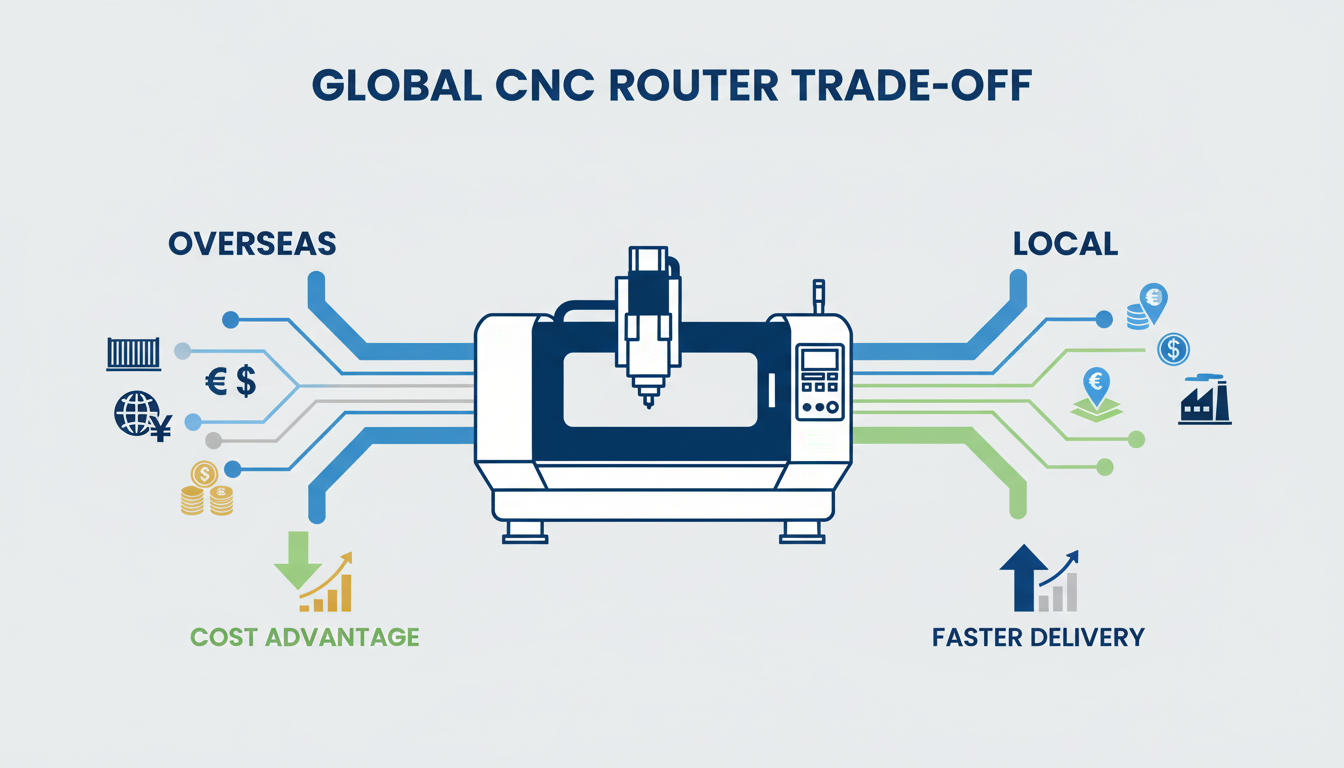

The Appeal of Overseas CNC Routers

The math seems simple: a CNC router that costs $25,000 from a US supplier might be available for $8,000-$12,000 shipped from overseas. That 50-70% savings is compelling, especially for small businesses watching every dollar.

But experienced buyers know that the purchase price is just the beginning. Before you wire money overseas, understand what you're really getting into—and what could go wrong.

Quality Risks and Inconsistency

Overseas manufacturing quality varies enormously, even from the same factory:

Component Substitution

- Quoted specifications may not match delivered components

- "Quality bearings" could mean anything from precision to generic

- Spindles advertised as one power level may test lower

- Linear rails and ball screws may be unbranded or lower grade

Assembly Variation

- Quality depends heavily on which workers assemble your machine

- End-of-shift or end-of-week machines may receive less attention

- Rush orders often have more problems

Batch-to-Batch Differences

- A great machine one month may be mediocre the next

- Component suppliers change without notice

- Cost-cutting measures may be implemented between your research and your order

Communication and Language Barriers

Even with English-speaking sales contacts, challenges persist:

Technical Misunderstandings

- Specifications may be interpreted differently

- Technical terms don't always translate precisely

- "Good quality" means different things in different contexts

Time Zone Issues

- 12+ hour time differences limit real-time communication

- Urgent questions may take 24-48 hours to resolve

- Problems escalate while waiting for responses

Cultural Differences

- Directness about problems varies by culture

- Saving face may prevent honest answers about issues

- Negotiation expectations differ significantly

Warranty and Legal Limitations

Your legal protections are limited when buying overseas:

Warranty Enforcement

- Warranties are only as good as your ability to enforce them

- International legal action is expensive and rarely practical

- Even legitimate warranty claims may be ignored or delayed

What Warranty Typically Covers

- Usually parts only—not labor, not shipping

- You pay to ship defective parts back (expensive for heavy items)

- You pay to install replacement parts

- Claims often require extensive documentation

What Happens in Practice

- Small problems: You fix them yourself to avoid the hassle

- Medium problems: Long negotiation for partial resolution

- Major problems: Often unresolved, machine becomes expensive learning experience

Technical Support Gaps

When something goes wrong—and eventually something will:

Remote Support Limitations

- Video calls across time zones are difficult to schedule

- Language barriers complicate troubleshooting

- They can't see exactly what's happening

- Documentation may be incomplete or poorly translated

No On-Site Help

- Nobody coming to diagnose complex problems

- You become your own technician

- Local technicians may be unfamiliar with your specific machine

Learning Curve

- Every problem becomes a research project

- YouTube and forums become your support system

- Significant time investment to develop expertise

Electrical and Safety Certification Issues

Overseas machines may not meet US standards:

Voltage and Power

- Many machines designed for 220V single-phase (common overseas)

- US shops often have 240V or need 3-phase conversion

- Transformers or rewiring may be needed

- Incorrect voltage damages components

Safety Certifications

- CE marking: European standard, not same as UL

- UL certification: Rarely present on overseas machines

- Insurance implications if non-certified equipment causes damage

- OSHA compliance considerations for commercial use

Electrical Code Compliance

- Wiring practices may not meet US electrical code

- Inspectors may flag non-compliant installations

- Retrofitting for compliance adds cost

Parts Availability and Lead Times

When components fail:

Common Wear Items

- Spindle bearings: May need replacement every 1-3 years

- Drive belts and couplings: Regular wear items

- Switches and sensors: Electronic components fail

Getting Replacement Parts

- Ordering from overseas: 2-4 weeks minimum

- Customs delays: Add unpredictable time

- Wrong parts shipped: Start the cycle again

- Machine down the entire time

Compatibility Issues

- Proprietary components may have no local equivalent

- Generic replacements may not fit or perform correctly

- Spindles especially problematic—specific mounting patterns

Hidden Costs That Erode Savings

The real cost is higher than the quoted price:

Shipping and Import Costs

- Ocean freight: $1,000-$4,000 depending on size

- Import duties: 0-5% depending on classification

- Customs broker fees: $200-$500

- Port handling and documentation: $200-$400

Delivery and Installation

- Trucking from port: $500-$2,000

- Liftgate service for heavy machines: $150-$300

- Forklift or machinery movers: $200-$500

- Electrical hookup: $200-$1,000

Your Time Investment

- Research and vetting: 20-40 hours

- Communication and ordering: 10-20 hours

- Customs paperwork: 5-10 hours

- Assembly and commissioning: 10-40 hours

- Learning without training: 40-100+ hours

Opportunity Cost

- What could you be doing with those hours?

- Delayed production while learning

- Mistakes and scrap during learning curve

Red Flags to Watch For

Warning signs when evaluating overseas suppliers:

- Prices dramatically lower than competitors – something is being cut

- Vague component specifications – "high quality" without brands or grades

- Pressure to order quickly – legitimate suppliers don't rush you

- Payment only by wire transfer – no buyer protection

- Won't do video calls showing factory – what are they hiding?

- No references from US customers – you'd be the test case

- Poor English in technical documents – support will be worse

- Different company names on communications – trading company, not manufacturer

Questions to Ask Before Purchasing

Due diligence checklist:

- What specific brands/models are used for spindle, rails, ball screws, controller?

- What certifications does the machine have? (Ask for documentation)

- Can you provide US customer references I can contact?

- What's included vs. additional cost? (Shipping, tooling, accessories)

- What voltage options are available?

- What warranty is offered and what does it actually cover?

- How do you handle warranty claims? What's the process?

- Where do I get replacement parts? What's typical lead time?

- Can you show me the machine being built via video call?

- What testing is done before shipping?

A Different Approach

The concerns above aren't meant to discourage you from saving money—they're meant to help you save money wisely.

Many buyers find that working with a US-based dealer who sources overseas equipment offers the best balance:

- Overseas pricing advantages

- Pre-vetted, quality-verified machines

- Local support and accountability

- Professional installation and training

- Someone to call when problems arise

Make an Informed Decision

Buying a CNC router from overseas can work well—but go in with eyes open. Understand the risks, budget realistically for total costs, and have a plan for support.

Contact our team to discuss your options. We can help you evaluate whether direct overseas purchase, working with a dealer, or a US-made machine makes the most sense for your specific situation. Browse our inventory to see pre-vetted equipment with full support.

Ready to get started?

Browse our equipment inventory or get in touch with our team for expert advice on your next project.