Everything you need to know about CO2 laser cutters. Learn how they work, what materials they cut, key specifications to compare, and how to choose the right machine for your needs and budget.

What Is a CO2 Laser Cutter?

A CO2 laser cutter uses a carbon dioxide gas mixture to generate a powerful infrared light beam. This beam is focused through mirrors and a lens onto the material surface, vaporizing or burning through it with precision. CO2 lasers have been the workhorse of laser cutting for decades, particularly for non-metal materials.

Unlike mechanical cutting tools that physically contact the workpiece, laser cutting is non-contact. This means no tool wear, no clamping forces, and the ability to cut intricate shapes that would be impossible with traditional methods.

How CO2 Lasers Work

Understanding the technology helps you make better buying decisions:

The Laser Tube

The heart of any CO2 laser is the tube filled with carbon dioxide, nitrogen, hydrogen, and helium gases. When electrical current excites this gas mixture, it produces infrared light at a wavelength of 10.6 micrometers. This wavelength is particularly effective at being absorbed by organic materials like wood, acrylic, leather, and fabric.

The Optical Path

Mirrors (typically three) direct the laser beam from the tube to the cutting head. A focusing lens concentrates this beam to a tiny point, achieving power densities high enough to vaporize material. The quality and alignment of these optics directly affects cut quality.

Motion System

The cutting head moves across the work surface using stepper or servo motors, guided by belts, lead screws, or linear rails. More expensive machines use linear rails and servo motors for faster, more accurate movement.

Cooling System

CO2 laser tubes generate significant heat and require cooling. Small machines may use air cooling, but most use water chillers. Proper cooling extends tube life and maintains consistent output power.

Types of CO2 Laser Cutters

Desktop Machines (40-60W)

Work area: Typically 12" x 8" to 24" x 16"

Best for: Hobbyists, small crafts, prototyping, small engraving businesses

Capabilities:

- Cut 3mm (1/8") acrylic and wood easily

- Cut 6mm (1/4") materials with multiple passes

- Engrave at reasonable speeds

- Detailed work on smaller items

Limitations:

- Smaller work area restricts project size

- Slower cutting on thicker materials

- Less suitable for production work

Price range: $500-$3,000

Mid-Size Machines (80-130W)

Work area: Typically 24" x 16" to 51" x 35"

Best for: Small businesses, sign makers, production work, professional makers

Capabilities:

- Cut 12mm (1/2") acrylic and wood in single pass

- Much faster cutting speeds

- Handle production volumes

- Larger projects in one piece

Considerations:

- Requires more space (machine + ventilation)

- Higher power consumption

- Larger water chiller needed

Price range: $3,000-$15,000

Industrial Machines (150W+)

Work area: 51" x 35" up to full sheet sizes (4' x 8')

Best for: Manufacturing, high-volume production, thick material cutting

Capabilities:

- Cut 20mm+ acrylic and thick hardwoods

- High-speed production cutting

- Continuous operation durability

- Advanced features (auto-focus, pass-through, camera positioning)

Considerations:

- Significant space and power requirements

- Industrial ventilation needed

- Higher maintenance costs

Price range: $15,000-$50,000+

Key Specifications to Compare

Wattage (Power Output)

Laser power determines cutting capability:

- 40W: 6mm acrylic, 6mm wood (with effort)

- 60W: 10mm acrylic, 10mm wood

- 80W: 12mm acrylic, 15mm wood

- 100W: 15mm acrylic, 20mm wood

- 130W: 20mm acrylic, 25mm wood

- 150W+: 25mm+ acrylic, thick hardwoods

These are guidelines—actual results depend on material density, laser quality, and settings.

Bed Size

Consider your typical and maximum project sizes. It's better to have more space than you think you need. Common sizes:

- 300 x 200mm (12" x 8") - Hobby

- 600 x 400mm (24" x 16") - Small business

- 900 x 600mm (36" x 24") - Professional

- 1300 x 900mm (51" x 35") - Production

- 1600 x 1000mm+ (63" x 40"+) - Industrial

Cutting Speed

Speed depends on material and thickness, but machine capability varies. Look for maximum travel speed specifications, but understand that actual cutting is much slower. Servo-driven machines are faster than stepper-driven ones.

Positioning Accuracy

Typically specified as ±0.01mm for quality machines. This matters for detailed work and consistent repeat cuts.

Z-Axis Travel

Determines the maximum material thickness you can accommodate. Some machines offer pass-through slots for longer pieces.

Materials CO2 Lasers Cut Well

Excellent Performance

- Acrylic (PMMA): Clean, polished edges. Cast acrylic engraves better than extruded.

- Wood: Plywood, MDF, hardwoods, veneers. Dark edge marks add character.

- Leather: Clean cuts, excellent for goods and fashion.

- Fabric: Sealed edges prevent fraying. Great for textiles.

- Paper/Cardboard: Intricate cuts impossible by other means.

- Rubber: Stamp making, gaskets.

- Foam: Packaging, inserts, craft foam.

Good for Engraving Only

- Glass: Surface engraving (fractures, doesn't cut)

- Coated metals: With marking sprays for contrast

- Anodized aluminum: Removes anodizing to reveal metal

- Stone: Surface engraving

Materials to Avoid

- PVC/Vinyl: Releases chlorine gas (toxic and corrosive)

- Polycarbonate: Burns, discolors, doesn't cut cleanly

- ABS: Melts, produces toxic fumes

- HDPE: Melts and warps

- Metals: CO2 wavelength reflects off metal surfaces

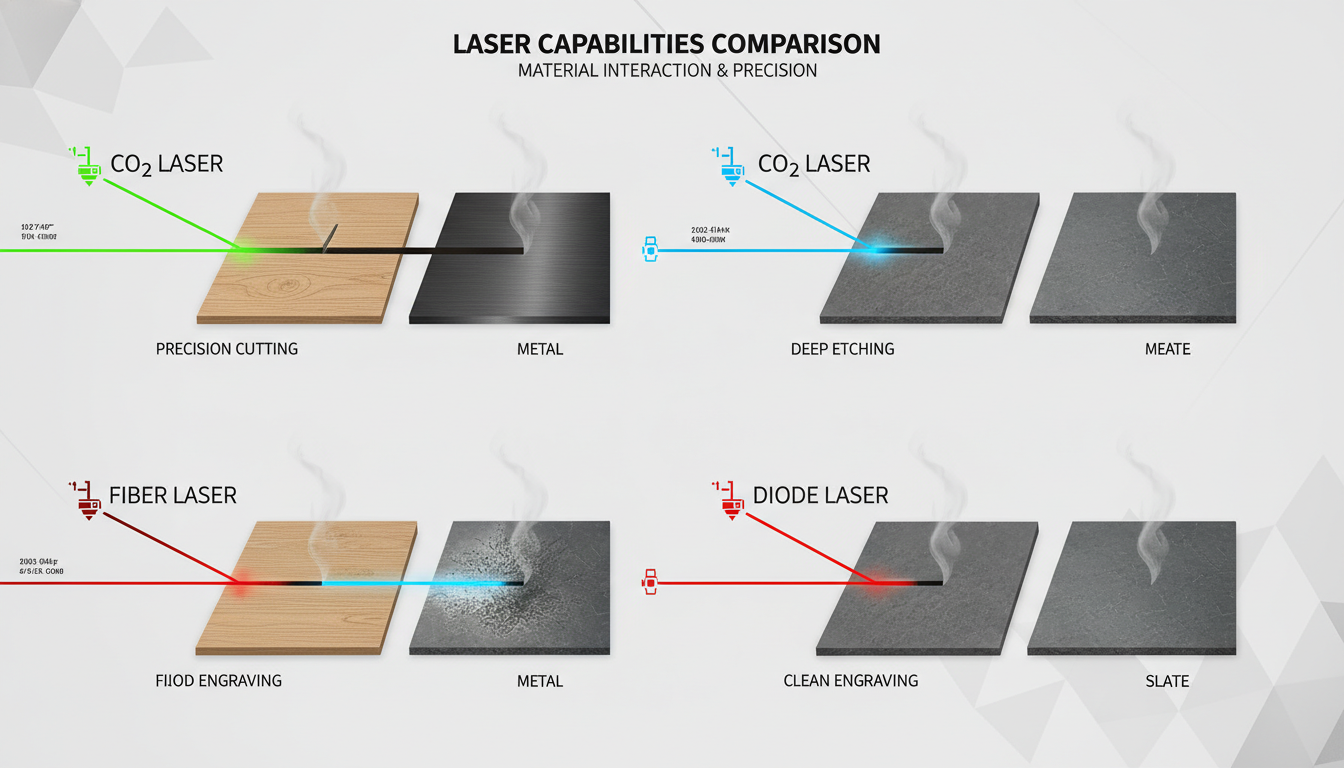

CO2 vs. Fiber vs. Diode Lasers

FeatureCO2FiberDiode Best forOrganic materialsMetalsHobby use Wood/acrylic cuttingExcellentPoorLimited Metal cuttingNoExcellentNo Initial costMediumHighLow Operating costMedium (tube replacement)LowLow Cutting speedFastVery fast (metal)Slow MaintenanceModerateLowLowBottom line: CO2 lasers are the standard for cutting wood, acrylic, leather, fabric, and other organic materials. Fiber lasers are for metal. Diode lasers are entry-level hobby tools.

Price Ranges by Capability

Entry Level ($500-$2,000)

- 40W glass tube lasers

- Smaller work areas

- Basic controllers

- Adequate for learning and hobby use

- May require upgrades for better performance

Prosumer ($2,000-$6,000)

- 60-80W tubes

- Larger work areas

- Better motion systems

- Improved controllers (Ruida, Trocen)

- Suitable for small business use

Professional ($6,000-$15,000)

- 80-130W tubes

- Production-ready build quality

- Linear rail guides

- Better ventilation and safety features

- Reliable for daily commercial use

Industrial ($15,000-$50,000+)

- High-power tubes (130W+)

- Large format capabilities

- RF (metal) tubes available

- Advanced features standard

- Built for continuous production

What to Look for When Buying

Build Quality Indicators

- Steel frame construction (not aluminum extrusions for larger machines)

- Linear rail guides (not wheels on extrusions)

- Quality belts and pulleys

- Proper enclosure with interlocks

- Honeycomb or blade bed included

Important Features

- Air assist: Blows air at cut point—essential for clean cuts

- Red dot pointer: Shows where laser will cut—very helpful

- Adjustable Z-axis: For focusing on different material heights

- Pass-through slots: For cutting longer materials

- Exhaust port: For connecting ventilation

- Water flow sensor: Protects tube from damage

Controller Quality

The controller affects ease of use and capabilities. Ruida controllers are the industry standard for quality Chinese lasers—avoid unknown or no-name controllers. Good controllers offer:

- Reliable file transfer (USB, Ethernet)

- Preview functionality

- Speed/power adjustment

- Position memory

- Compatible with LightBurn software

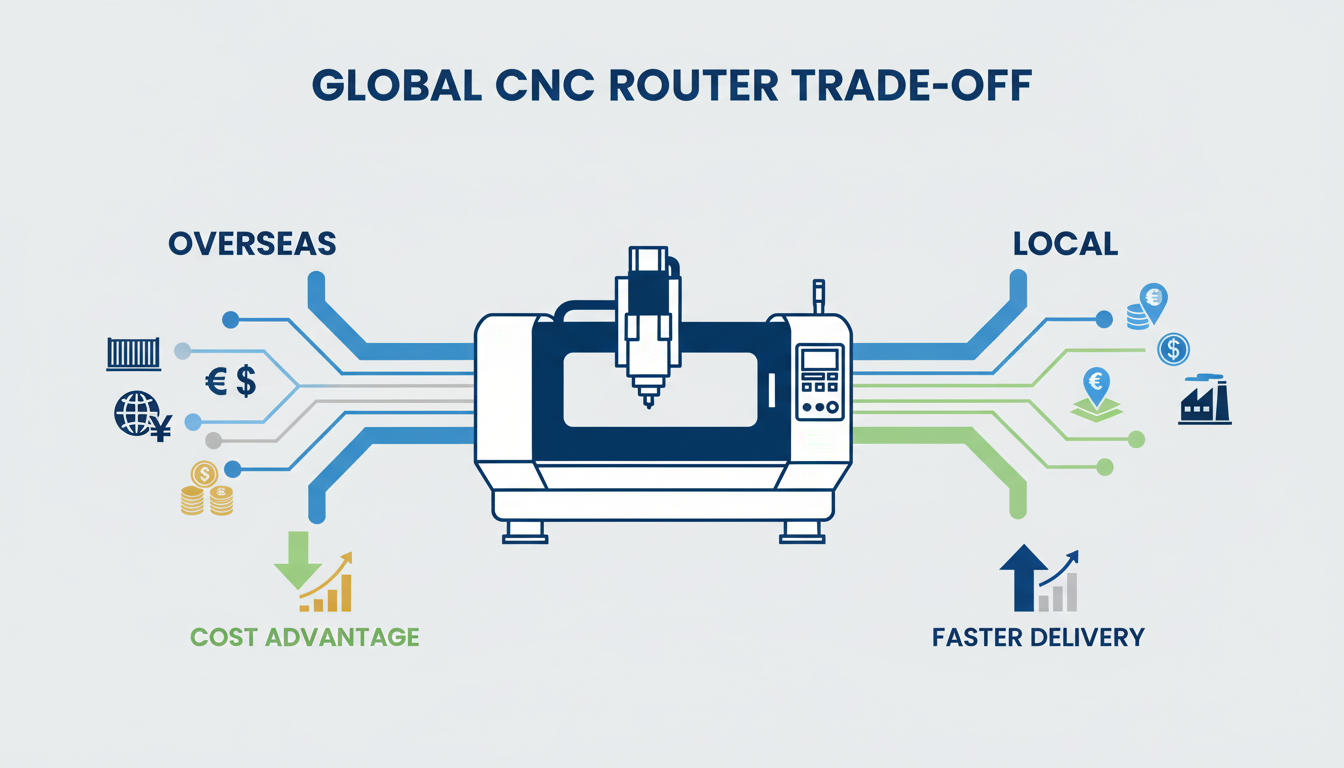

Sourcing from China with Local Support

The reality of CO2 laser cutters: most machines at every price point are manufactured in China. The difference is in quality control, configuration, support, and service.

Direct Import Challenges

- Quality varies dramatically between factories

- Limited recourse if problems arise

- Shipping damage claims are difficult

- Setup and calibration is your responsibility

- Technical support across time zones and languages

- Parts sourcing for repairs

The Smarter Approach

Working with a US-based supplier who sources from quality Chinese manufacturers gives you:

- Pre-purchase quality verification

- Machines configured for US electrical standards

- Professional setup and training available

- Local technical support

- Warranty backed by a US company

- Parts availability

Ready to Find the Right CO2 Laser Cutter?

Whether you're starting a laser cutting business, adding capabilities to your shop, or upgrading from an entry-level machine, choosing the right CO2 laser cutter is a significant decision.

Contact our team to discuss your specific needs. We'll help you understand what specifications actually matter for your applications and find equipment that fits your requirements and budget.

Browse our laser equipment selection to see what's currently available with full US support.

Ready to get started?

Browse our equipment inventory or get in touch with our team for expert advice on your next project.