Explore desktop CNC routers perfect for small spaces. Learn about compact machines that deliver professional results for signs, prototypes, and small-batch production.

The Rise of Desktop CNC Routers

Desktop CNC routers pack professional capabilities into compact packages. These machines fit on a workbench or dedicated stand, making them ideal for small shops, makerspaces, and home workshops where space is at a premium. Despite their size, modern desktop CNC routers deliver impressive results.

Benefits of Desktop CNC Routers

Space Efficiency

Desktop machines typically require just 2' x 3' of floor space including workspace around the machine. This makes CNC routing accessible in apartments, garages, and small commercial spaces.

Lower Cost of Entry

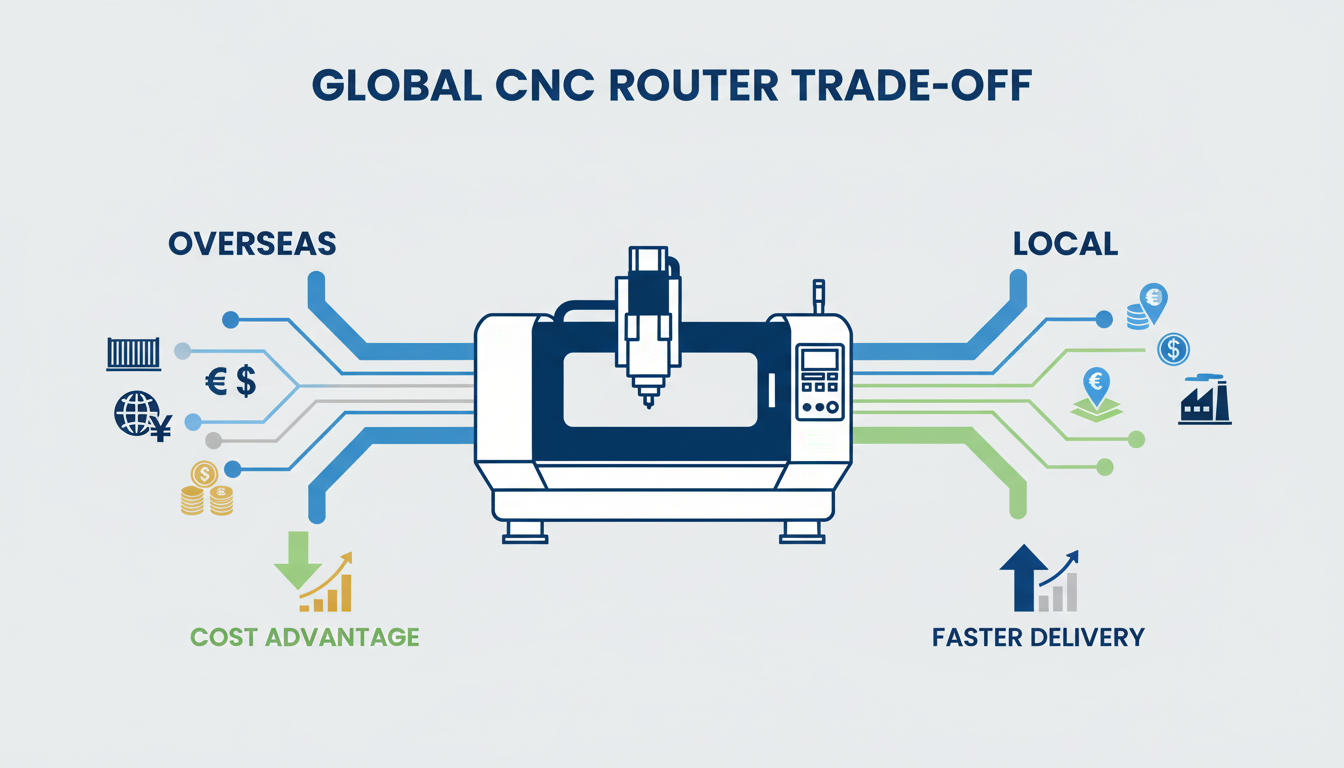

Compact machines cost less to manufacture and ship. You can get started with a capable desktop CNC router for under $2,000, with premium options around $5,000.

Standard Power

Desktop routers run on standard household electrical circuits. No special wiring or high-amperage service required.

Portability

Smaller machines can be moved when needed, stored when not in use, or transported to job sites and events.

Quieter Operation

Smaller spindles and enclosed designs reduce noise compared to full-size industrial machines.

Typical Specifications

Work Area

Desktop CNC routers typically offer:

- X-axis: 12" to 24"

- Y-axis: 12" to 24"

- Z-axis: 2" to 4" (cutting depth)

Spindle Options

- Trim routers: 500W-1000W, affordable and replaceable

- Compact spindles: 800W-1.5kW VFD spindles for quieter operation

Frame Construction

- Aluminum extrusion (most common)

- Cast aluminum for premium machines

- Some fully enclosed designs

Ideal Applications

Sign Making

Desktop routers excel at small to medium signs. V-carved lettering, raised graphics, and detailed logos are all achievable within the compact work area.

Prototyping

Product designers and engineers use desktop CNC routers to create functional prototypes quickly. Test fits, visual models, and small production runs are all practical.

Jewelry and Small Items

The precision of desktop machines suits detailed work on small items. Jewelry components, keychains, and decorative objects are popular projects.

Educational Settings

Schools and makerspaces favor desktop machines for their safety, manageable size, and lower replacement costs if damaged.

PCB Manufacturing

With appropriate bits and settings, desktop routers can mill circuit boards for electronics prototyping.

Enclosed vs. Open Frame

Enclosed Desktop CNC Routers

Machines with full enclosures offer:

- Better dust and chip containment

- Reduced noise levels

- Enhanced safety

- Climate control for consistent operation

Open Frame Designs

Open machines provide:

- Lower cost

- Easier access for workholding

- Better visibility during operation

- Simpler maintenance

What to Look For

Rigidity Relative to Size

Smaller doesn't mean less precise. Quality desktop machines maintain tight tolerances through careful engineering and appropriate component selection.

Spindle Mounting

How the spindle attaches affects consistency. Look for positive positioning and minimal runout in the spindle assembly.

Dust Management

Integrated dust boots and enclosures matter more in small spaces where dust disperses throughout the room.

Software Compatibility

Ensure the machine works with software you want to use. Some machines lock you into proprietary ecosystems.

Types of Desktop CNC Routers

- Premium enclosed machines: Full enclosure for precise work and clean operation

- Compact enclosed routers: Excellent dust management in a small footprint

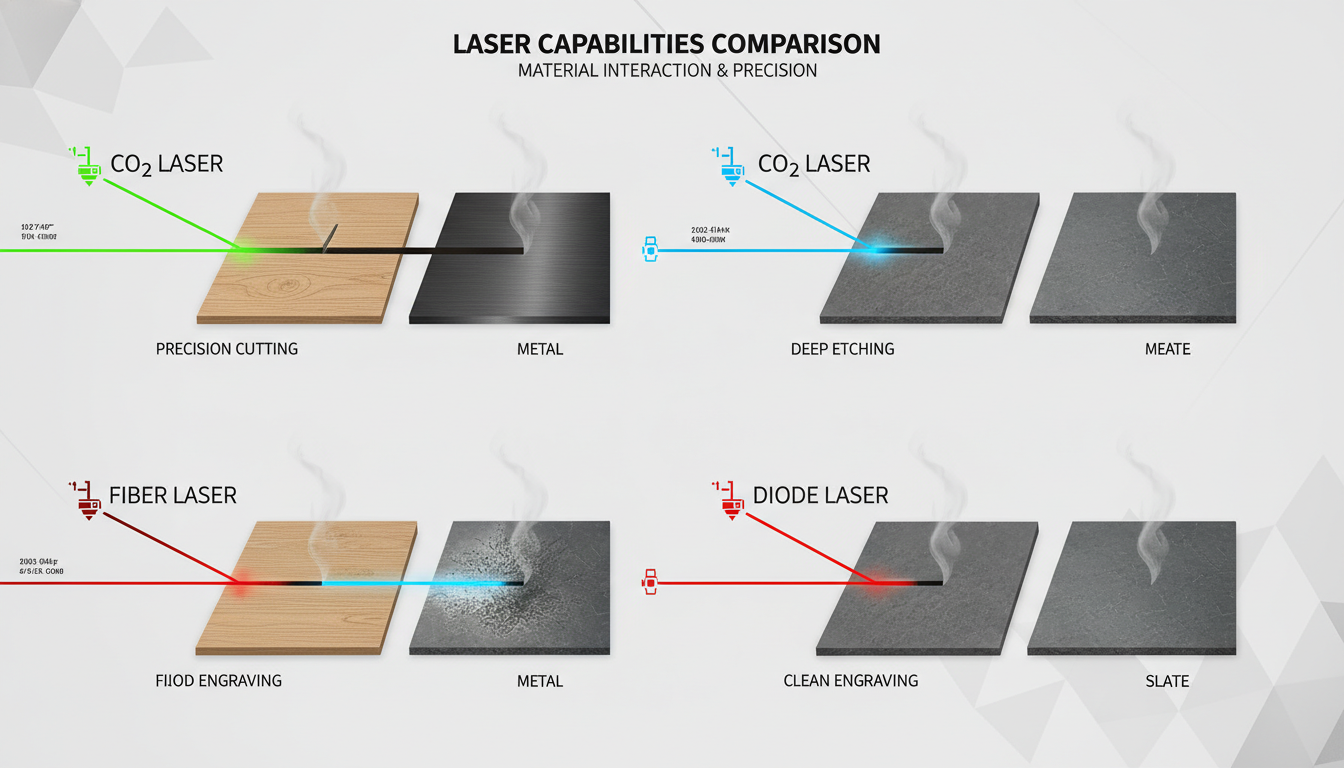

- Modular multi-tool systems: Combine CNC routing, 3D printing, and laser engraving

- Budget desktop routers: Affordable entry with larger work areas

- Compact hobby platforms: Established designs scaled to desktop size

Maximizing Small Format Machines

Tiling for Larger Projects

Cut larger designs in sections by repositioning material between operations. Software like VCarve supports tiling workflows.

Efficient Material Use

Nesting software optimizes part placement to minimize waste from limited sheet sizes.

Two-Sided Machining

Flip material to machine both sides, effectively doubling what you can create within the Z-axis limitation.

Find Your Desktop CNC Router

Desktop CNC routers prove that capability doesn't require a factory floor. The right compact machine enables professional-quality work in any space.

Explore our desktop CNC router selection to find the perfect fit for your workshop. Our team can help you evaluate options based on your specific space constraints and project needs.

Ready to get started?

Browse our equipment inventory or get in touch with our team for expert advice on your next project.