Learn about specialty CNC equipment from China including bending machines, laser cutters, and other specialized machinery for metal fabrication.

Beyond Traditional CNC Routers and Mills

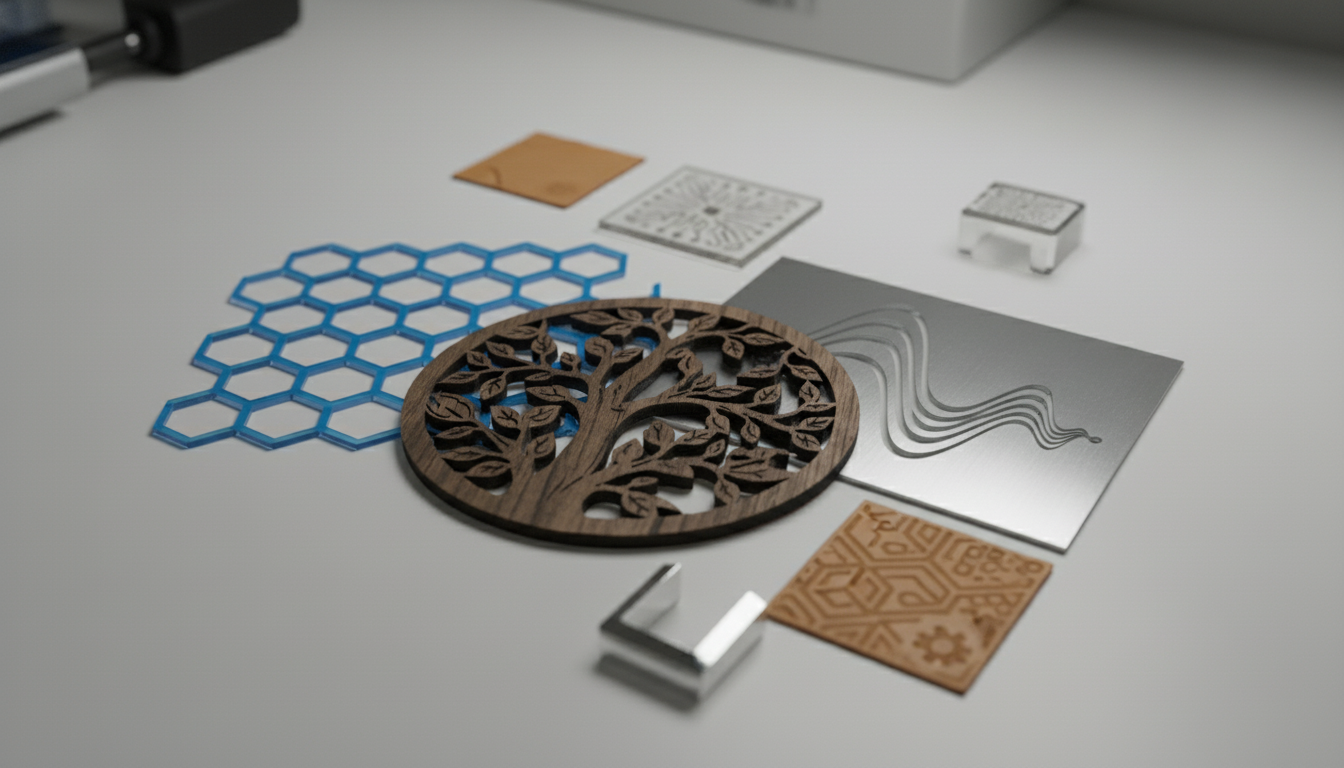

While CNC routers and milling machines get most of the attention, Chinese manufacturers produce a wide range of specialty CNC equipment. These machines serve specific applications in metal fabrication, laser processing, and specialized manufacturing.

CNC Bending Machines

Computer-controlled bending equipment for sheet metal and structural forming:

CNC Press Brakes

- Function: Bend sheet metal to precise angles

- Capacity: From small benchtop units to 1000+ ton industrial machines

- Features: CNC backgauge, angle measurement, crowning compensation

- Applications: Enclosures, brackets, structural components

CNC Tube and Pipe Benders

- Function: Create precise bends in tubes and pipes

- Types: Rotary draw, compression, roll bending

- Applications: Handrails, exhaust systems, furniture, roll cages

Roll Forming Equipment

- Function: Create continuous profiles from sheet metal

- Applications: Roofing panels, structural channels, trim

Quality Considerations for Bending Equipment

- Frame rigidity affects bend accuracy

- Hydraulic system quality determines longevity

- CNC controller capabilities and ease of programming

- Tooling compatibility and availability

- Safety systems and certifications critical for press brakes

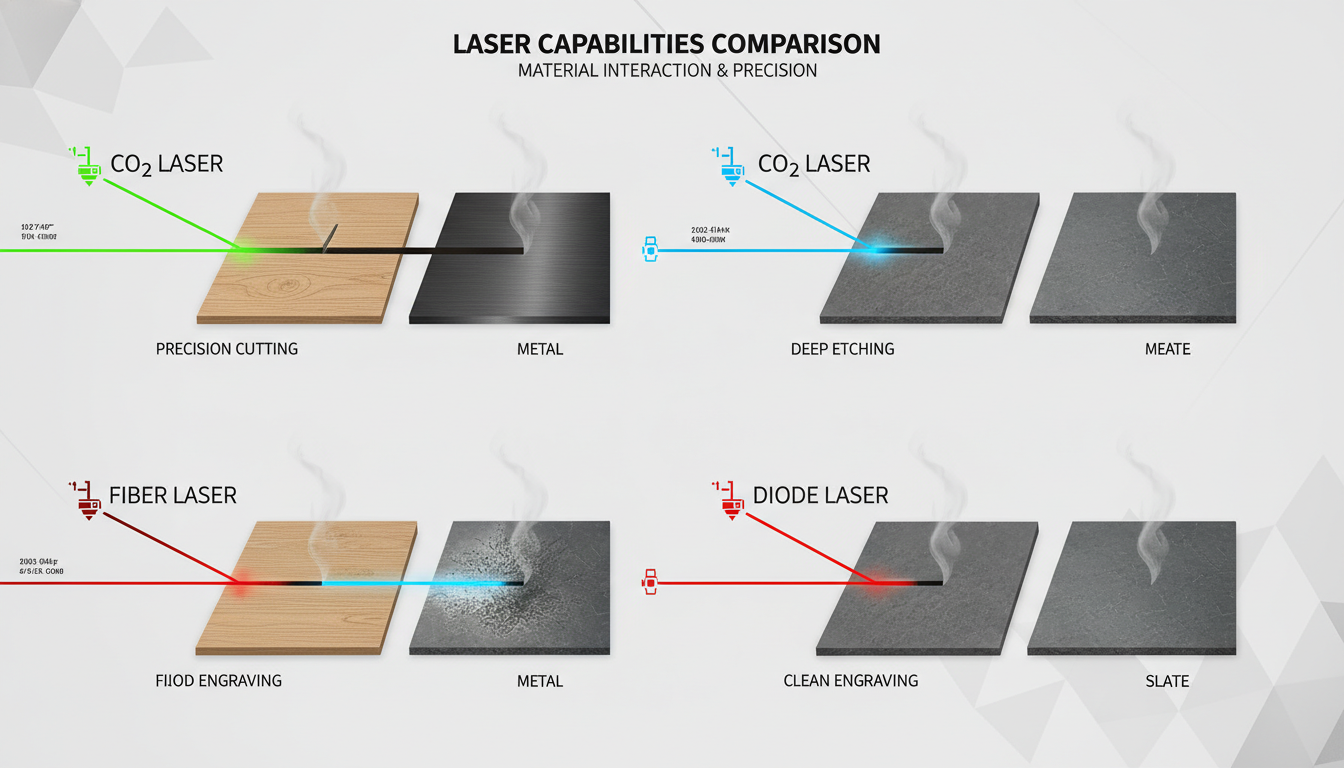

Laser Cutting Equipment

Chinese manufacturers produce both CO2 and fiber laser systems:

Fiber Laser Cutters (Metal)

- Function: Cut sheet metal with high speed and precision

- Power range: 500W to 20,000W+ from Chinese sources

- Materials: Steel, stainless, aluminum, brass, copper

- Advantages: Fast cutting, low operating cost, minimal maintenance

- Applications: Sheet metal fabrication, parts manufacturing, signage

CO2 Laser Cutters/Engravers

- Function: Cut and engrave non-metallic materials

- Power range: 40W to 300W+ common

- Materials: Wood, acrylic, leather, fabric, paper, some plastics

- Applications: Signage, crafts, prototyping, packaging

Precious Metal Laser Processing

- Gold laser cutting systems: Specialized for jewelry manufacturing

- Features: Fine beam for intricate work, enclosed for material recovery

- Applications: Jewelry, dental, electronics

Laser Quality Considerations

- Laser source quality: Affects cut quality and lifespan

- Motion system: Determines speed and accuracy

- Control system: Software capabilities and file compatibility

- Enclosure and ventilation: Safety critical, especially for CO2

- Beam delivery system: Mirrors and optics quality (CO2)

- Assist gas systems: Required for fiber laser metal cutting

Other Specialty Equipment

CNC Plasma Cutters

- Function: Cut thick metal with plasma arc

- Advantages: Lower cost than laser for thick materials

- Limitations: Wider kerf, more dross than laser

- Best for: Structural steel, heavy plate fabrication

CNC Waterjet Cutters

- Function: Cut any material with high-pressure water and abrasive

- Advantages: No heat-affected zone, cuts thick materials

- Limitations: Slower than laser, ongoing abrasive cost

- Best for: Stone, glass, thick metals, heat-sensitive materials

CNC Stone/Marble Routers

- Function: Cut and shape stone, granite, marble

- Features: Water cooling, heavy-duty frames, diamond tooling

- Applications: Countertops, monuments, architectural elements

CNC Foam Cutters

- Function: Cut foam materials (EPS, polyurethane, etc.)

- Types: Hot wire, router, oscillating knife

- Applications: Packaging, signs, insulation, molds

Evaluating Specialty Equipment

Application-Specific Requirements

- What materials and thicknesses will you process?

- What production volume do you need?

- What precision and edge quality is required?

- What file formats and workflow do you use?

Safety Certifications Matter

Especially important for:

- Laser equipment: Enclosed beam paths, interlocks, proper ventilation

- Press brakes: Light curtains, two-hand controls, guard systems

- Plasma/waterjet: Electrical safety, emergency stops

Consumables and Operating Costs

- Laser: Gases, lens/mirror replacement, laser tube/source life

- Plasma: Consumable torch parts, gas

- Waterjet: Abrasive, nozzle wear, pump maintenance

- Bending: Tooling wear, hydraulic fluid

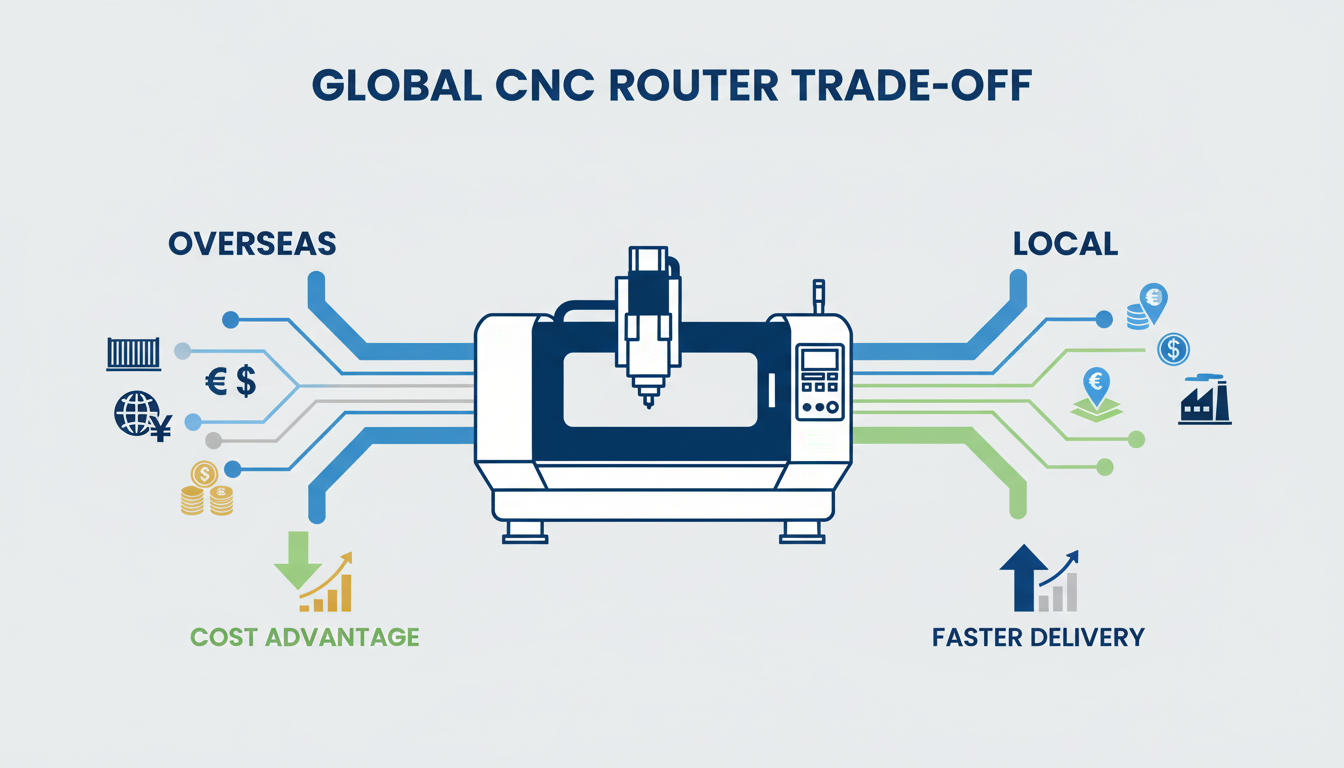

The Importance of Local Support

Specialty equipment often has higher support requirements than standard CNC:

Training Complexity

- Safety procedures specific to each technology

- Material-specific settings and techniques

- Maintenance requirements

Maintenance Demands

- Laser optics alignment and cleaning

- Hydraulic system service for press brakes

- High-pressure pump maintenance for waterjet

Parts and Consumables

- Specialty parts not always available locally

- Consumables needed regularly for operation

- Downtime cost when waiting for international shipments

Finding the Right Equipment Partner

For specialty equipment, the supplier relationship matters even more than for standard CNC:

Questions to Ask

- What training is provided with the machine?

- Who handles service and support in my area?

- What consumables are needed and where do I get them?

- What warranty is offered and who honors it?

- Can you provide references from similar applications?

- What safety certifications does the equipment have?

Explore Your Options

Specialty CNC equipment can transform your manufacturing capabilities—but the increased complexity makes proper support essential.

Contact us to discuss your specialty equipment needs. We can help you evaluate options and ensure you have the support to operate safely and productively. Browse our equipment inventory to see available machines.

Ready to get started?

Browse our equipment inventory or get in touch with our team for expert advice on your next project.