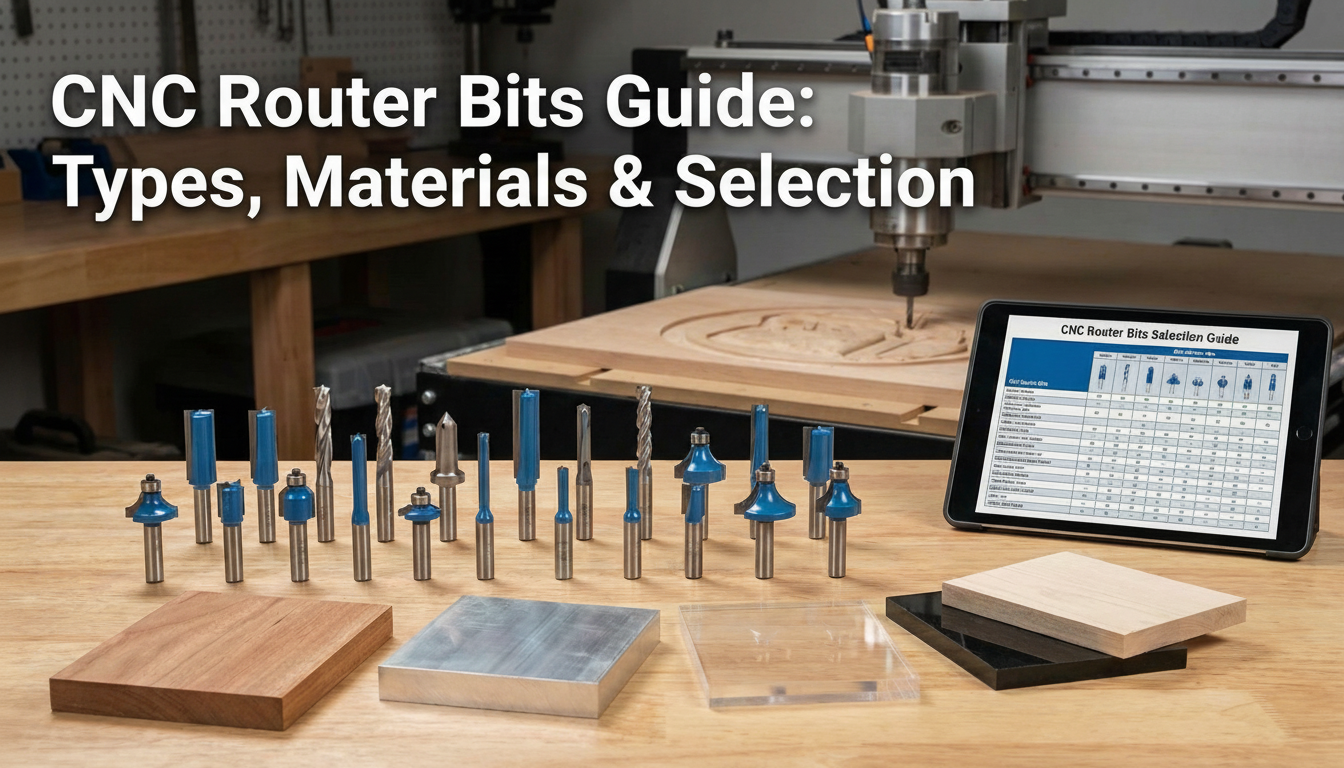

Master CNC router bit selection with our comprehensive guide covering bit types, materials, coatings, and how to choose the right bit for any project.

Understanding CNC Router Bits

Choosing the right CNC router bit is essential for achieving quality results. The wrong bit can lead to poor surface finish, excessive wear, and even damaged workpieces. This comprehensive guide covers everything you need to know about CNC router bits to make informed selections for your projects.

Types of CNC Router Bits

Different cutting operations require different bit geometries. Here are the most common types:

End Mills

End mills are the workhorses of CNC routing. They cut on both the end and sides, making them versatile for profiling, pocketing, and slotting operations.

- Flat End Mills: Create flat-bottomed pockets and sharp inside corners. Available in 1-4+ flute configurations.

- Ball Nose End Mills: Feature a rounded tip for 3D contouring and smooth surface finishing.

- Bull Nose End Mills: Combine a flat bottom with rounded corners for stronger edges and smooth fillets.

V-Bits

V-bits have a pointed tip with angled sides, typically at 60, 90, or 120 degrees. They're essential for:

- V-carving text and decorative elements

- Chamfering edges

- Engraving fine details

- Creating beveled edges

Straight Bits

Straight bits cut with their sides only and are designed for edge work, dadoes, and rabbets. They produce clean vertical walls but can't plunge directly into material.

Compression Bits

Compression bits combine up-cut and down-cut geometry in one tool. The bottom portion cuts upward while the top cuts downward, creating clean edges on both faces of sheet materials like plywood and MDF.

Spiral Bits

Spiral (or helical) bits have flutes that wrap around the tool body:

- Up-Cut Spirals: Pull chips up and out of the cut. Excellent chip evacuation but may cause tearout on the top surface.

- Down-Cut Spirals: Push chips downward for clean top surfaces but can pack chips in deep cuts.

Specialty Bits

Many specialized bits exist for specific applications:

- Surfacing Bits: Large diameter bits for flattening spoilboards and workpiece surfaces

- Tapered Bits: For draft angles and 3D relief carving

- Diamond Drag Bits: Spring-loaded points for engraving without rotation

- Thread Mills: For cutting threads in various materials

Bit Materials

The material a bit is made from determines its durability, heat resistance, and suitable applications:

High-Speed Steel (HSS)

HSS bits are affordable and work well for wood and soft materials. They're easy to resharpen but wear faster than harder materials. Good for hobbyists and light-duty work.

Solid Carbide

Carbide bits are harder than HSS and maintain sharp edges longer, especially when cutting abrasive materials. They're more brittle and require careful handling but offer superior performance for most CNC work.

Carbide-Tipped

These bits have carbide cutting edges brazed onto a steel body. They offer a balance between cost and performance, commonly used in larger diameter bits.

Diamond-Coated

Diamond coatings extend tool life dramatically when cutting highly abrasive materials like carbon fiber, fiberglass, and stone. The coating provides extreme wear resistance.

Coatings and Their Benefits

Surface coatings enhance bit performance in various ways:

TiN (Titanium Nitride)

The gold-colored coating increases surface hardness and heat resistance. Commonly used for general-purpose cutting.

TiAlN (Titanium Aluminum Nitride)

Purple or dark-colored coating excels in high-temperature applications. Excellent for harder materials and higher speeds.

ZrN (Zirconium Nitride)

Light gold coating reduces friction and prevents material buildup. Ideal for aluminum and other non-ferrous metals.

Choosing the Right Bit

Consider these factors when selecting bits:

Material Being Cut

- Softwood: Sharp HSS or carbide bits with 2 flutes work well

- Hardwood: Solid carbide with 2-3 flutes for clean cuts

- Plywood/MDF: Compression bits prevent tearout on both surfaces

- Plastics: Single flute O-flute bits prevent melting

- Aluminum: ZrN-coated bits with fewer flutes, single flute for soft alloys

Cut Type

- Profiling: End mills with appropriate diameter for curves

- Pocketing: End mills sized for efficient material removal

- Engraving: V-bits or small diameter end mills

- 3D Carving: Ball nose bits in various sizes for roughing and finishing

Flute Count

The number of flutes affects cut quality and chip evacuation:

- 1-2 Flutes: Better chip evacuation for softer materials and deeper cuts

- 3-4 Flutes: Smoother finishes for harder materials at higher feed rates

Bit Maintenance

Extend bit life with proper care:

- Clean after use: Remove pitch and resin buildup with appropriate cleaners

- Store properly: Keep bits in protective cases or holders to prevent damage

- Inspect regularly: Check for chips, wear, and dullness before use

- Run correct speeds: Follow manufacturer recommendations for RPM and feed rates

Build Your Bit Collection

A well-equipped shop needs a variety of bits. Start with these essentials:

- 1/4" and 1/8" flat end mills for general cutting

- 60 and 90-degree V-bits for carving

- Ball nose bits in 1/4" and 1/8" for 3D work

- Surfacing bit for spoilboard maintenance

Questions about bits for your specific applications? Contact our team for expert recommendations and sourcing assistance.

Ready to get started?

Browse our equipment inventory or get in touch with our team for expert advice on your next project.